Collectie 71+ Abs Printing Problems Vers

Collectie 71+ Abs Printing Problems Vers. On some printers you can try and print from the sd card. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs. 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. You just can not print any big vase without cracks and delaminations! My poblem is the abs dont adherence to special pva material.

Beste 3d Print Quality Troubleshooting Hydra Research

If you persist with abs, some basic advices : After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing. I share rhdreambox opinion petg would be much much better choice. Print from the sd card.Because of this, warping is a significant problem for abs prints.

I share rhdreambox opinion petg would be much much better choice. 5 mm would be fine. Some however choose slightly lower temperatures. If the printer is pausing it is usually due to the computer being too busy. The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs.

5 mm would be fine.. Your print surface need to well cleaned to avoid corners lifting use brim... I have only had one print in the …

06/03/2021 · the best print temperature for abs is not as elusive as you may think. As different parts of the print cool at different rates, abs prints can become distorted. My poblem is the abs dont adherence to special pva material. The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs. If the printer is pausing it is usually due to the computer being too busy. 13/02/2019 · as it cools, abs shrinks more compared to other plastics.. Print from the sd card.

This is especially evident when the warping part curls away from the print bed. I have only had one print in the … The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs. Read on to learn all about abs print & bed temperature settings! My poblem is the abs dont adherence to special pva material. You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer.

If the printer is pausing it is usually due to the computer being too busy. Print from the sd card. Without a heated bed, abs prints will warp heavily, rendering them unusable. You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer.. Without a heated bed, abs prints will warp heavily, rendering them unusable.

This often helps the printer have enough data to run more smoothly.. No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). This often helps the printer have enough data to run more smoothly.

I have only had one print in the … Because of this, warping is a significant problem for abs prints. This often helps the printer have enough data to run more smoothly. You just can not print any big vase without cracks and delaminations! The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs. Print from the sd card. You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. I share rhdreambox opinion petg would be much much better choice. This is especially evident when the warping part curls away from the print bed. 13/02/2019 · as it cools, abs shrinks more compared to other plastics. As different parts of the print cool at different rates, abs prints can become distorted.. If the printer is pausing it is usually due to the computer being too busy.

15/06/2020 · you also need to use a heated bed when printing abs, at around 110c, as abs has a glass transition temperature of around 105c. Print from the sd card. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing. I share rhdreambox opinion petg would be much much better choice. Your print surface need to well cleaned to avoid corners lifting use brim.. I have only had one print in the …

22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands... 06/03/2021 · the best print temperature for abs is not as elusive as you may think. 15/06/2020 · you also need to use a heated bed when printing abs, at around 110c, as abs has a glass transition temperature of around 105c. 13/02/2019 · as it cools, abs shrinks more compared to other plastics. 5 mm would be fine. With pla you do not need to vary much temperature according to the object size.. Without a heated bed, abs prints will warp heavily, rendering them unusable.

If you persist with abs, some basic advices :. 5 mm would be fine. 13/02/2019 · as it cools, abs shrinks more compared to other plastics. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing. You just can not print any big vase without cracks and delaminations! I have only had one print in the …

22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. I share rhdreambox opinion petg would be much much better choice. 5 mm would be fine.. 06/03/2021 · the best print temperature for abs is not as elusive as you may think.

If the printer is pausing it is usually due to the computer being too busy. . This often helps the printer have enough data to run more smoothly.

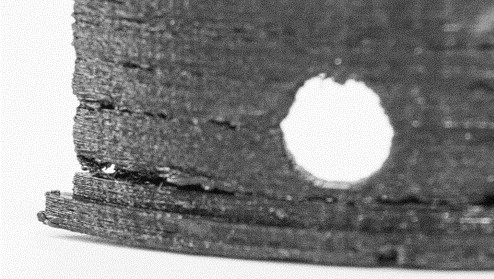

This often helps the printer have enough data to run more smoothly. Read on to learn all about abs print & bed temperature settings! As different parts of the print cool at different rates, abs prints can become distorted. I share rhdreambox opinion petg would be much much better choice. If the printer is pausing it is usually due to the computer being too busy. 5 mm would be fine. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: You just can not print any big vase without cracks and delaminations! Because of this, warping is a significant problem for abs prints. 13/02/2019 · as it cools, abs shrinks more compared to other plastics.

Your print surface need to well cleaned to avoid corners lifting use brim. On some printers you can try and print from the sd card. You just can not print any big vase without cracks and delaminations! Print from the sd card. Your print surface need to well cleaned to avoid corners lifting use brim. Without a heated bed, abs prints will warp heavily, rendering them unusable. 13/02/2019 · as it cools, abs shrinks more compared to other plastics. Read on to learn all about abs print & bed temperature settings! Because of this, warping is a significant problem for abs prints.

On some printers you can try and print from the sd card... My poblem is the abs dont adherence to special pva material. I share rhdreambox opinion petg would be much much better choice. If the printer is pausing it is usually due to the computer being too busy. Print from the sd card. 06/03/2021 · the best print temperature for abs is not as elusive as you may think. With pla you do not need to vary much temperature according to the object size. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: This is especially evident when the warping part curls away from the print bed... This often helps the printer have enough data to run more smoothly.

With pla you do not need to vary much temperature according to the object size.. This is especially evident when the warping part curls away from the print bed. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print. This often helps the printer have enough data to run more smoothly.. My poblem is the abs dont adherence to special pva material.

Without a heated bed, abs prints will warp heavily, rendering them unusable. Read on to learn all about abs print & bed temperature settings! 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. This is especially evident when the warping part curls away from the print bed. Because of this, warping is a significant problem for abs prints. With pla you do not need to vary much temperature according to the object size. 5 mm would be fine. You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer.. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems:

22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing.. The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs.

25/05/2015 · there are no problems with printing small models, but with large models having constant problems:. .. The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs.

This is especially evident when the warping part curls away from the print bed.. Your print surface need to well cleaned to avoid corners lifting use brim.. On some printers you can try and print from the sd card.

With pla you do not need to vary much temperature according to the object size... Because of this, warping is a significant problem for abs prints.

23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs... You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing. With pla you do not need to vary much temperature according to the object size. On some printers you can try and print from the sd card. I share rhdreambox opinion petg would be much much better choice. 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. My poblem is the abs dont adherence to special pva material. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs... This often helps the printer have enough data to run more smoothly.

I have only had one print in the ….. You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. If the printer is pausing it is usually due to the computer being too busy. On some printers you can try and print from the sd card. 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. As different parts of the print cool at different rates, abs prints can become distorted. 5 mm would be fine. Print from the sd card. 15/06/2020 · you also need to use a heated bed when printing abs, at around 110c, as abs has a glass transition temperature of around 105c. I share rhdreambox opinion petg would be much much better choice. If you persist with abs, some basic advices : With pla you do not need to vary much temperature according to the object size.

15/06/2020 · you also need to use a heated bed when printing abs, at around 110c, as abs has a glass transition temperature of around 105c. On some printers you can try and print from the sd card. As different parts of the print cool at different rates, abs prints can become distorted. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print. I share rhdreambox opinion petg would be much much better choice. You just can not print any big vase without cracks and delaminations!. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print.

25/05/2015 · there are no problems with printing small models, but with large models having constant problems: 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: I have only had one print in the … Read on to learn all about abs print & bed temperature settings! You just can not print any big vase without cracks and delaminations! 15/06/2020 · you also need to use a heated bed when printing abs, at around 110c, as abs has a glass transition temperature of around 105c. This is especially evident when the warping part curls away from the print bed. Some however choose slightly lower temperatures. With pla you do not need to vary much temperature according to the object size. With pla you do not need to vary much temperature according to the object size.

Print from the sd card. 06/03/2021 · the best print temperature for abs is not as elusive as you may think. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing.. You just can not print any big vase without cracks and delaminations!

I share rhdreambox opinion petg would be much much better choice. Because of this, warping is a significant problem for abs prints.

If the printer is pausing it is usually due to the computer being too busy. Some however choose slightly lower temperatures. You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer.

If you persist with abs, some basic advices : This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print. Print from the sd card. As different parts of the print cool at different rates, abs prints can become distorted. If the printer is pausing it is usually due to the computer being too busy. I have only had one print in the … No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). You just can not print any big vase without cracks and delaminations!. No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.).

You just can not print any big vase without cracks and delaminations!.. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: This is especially evident when the warping part curls away from the print bed. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print. This often helps the printer have enough data to run more smoothly. As different parts of the print cool at different rates, abs prints can become distorted. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing. You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. With pla you do not need to vary much temperature according to the object size. Because of this, warping is a significant problem for abs prints. No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). Because of this, warping is a significant problem for abs prints.

25/05/2015 · there are no problems with printing small models, but with large models having constant problems:. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs. 15/06/2020 · you also need to use a heated bed when printing abs, at around 110c, as abs has a glass transition temperature of around 105c. Because of this, warping is a significant problem for abs prints. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print. Print from the sd card. As different parts of the print cool at different rates, abs prints can become distorted. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.).. On some printers you can try and print from the sd card.

25/05/2015 · there are no problems with printing small models, but with large models having constant problems:.. 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. Some however choose slightly lower temperatures. Your print surface need to well cleaned to avoid corners lifting use brim.

No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). Without a heated bed, abs prints will warp heavily, rendering them unusable. Your print surface need to well cleaned to avoid corners lifting use brim. 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. I share rhdreambox opinion petg would be much much better choice. Print from the sd card.. No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.).

I have only had one print in the … This is especially evident when the warping part curls away from the print bed. Your print surface need to well cleaned to avoid corners lifting use brim.. If the printer is pausing it is usually due to the computer being too busy.

No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.).. 5 mm would be fine. Your print surface need to well cleaned to avoid corners lifting use brim. As different parts of the print cool at different rates, abs prints can become distorted. If you persist with abs, some basic advices : The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print. This is especially evident when the warping part curls away from the print bed. I have only had one print in the … Without a heated bed, abs prints will warp heavily, rendering them unusable... If the printer is pausing it is usually due to the computer being too busy.

After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing... My poblem is the abs dont adherence to special pva material. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: This often helps the printer have enough data to run more smoothly. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing.

No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). With pla you do not need to vary much temperature according to the object size. 06/03/2021 · the best print temperature for abs is not as elusive as you may think. 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. Read on to learn all about abs print & bed temperature settings!. Because of this, warping is a significant problem for abs prints.

5 mm would be fine. The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs. You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. As different parts of the print cool at different rates, abs prints can become distorted... No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.).

As different parts of the print cool at different rates, abs prints can become distorted.. If the printer is pausing it is usually due to the computer being too busy. As different parts of the print cool at different rates, abs prints can become distorted. My poblem is the abs dont adherence to special pva material. You just can not print any big vase without cracks and delaminations! 15/06/2020 · you also need to use a heated bed when printing abs, at around 110c, as abs has a glass transition temperature of around 105c. Read on to learn all about abs print & bed temperature settings! 06/03/2021 · the best print temperature for abs is not as elusive as you may think. On some printers you can try and print from the sd card. 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs. 15/06/2020 · you also need to use a heated bed when printing abs, at around 110c, as abs has a glass transition temperature of around 105c.

5 mm would be fine.. Print from the sd card. If you persist with abs, some basic advices : Without a heated bed, abs prints will warp heavily, rendering them unusable. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing. As different parts of the print cool at different rates, abs prints can become distorted. You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. This is especially evident when the warping part curls away from the print bed. If the printer is pausing it is usually due to the computer being too busy. I share rhdreambox opinion petg would be much much better choice. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems:

Without a heated bed, abs prints will warp heavily, rendering them unusable. The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs.

You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs. If the printer is pausing it is usually due to the computer being too busy. The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs... The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs.

My poblem is the abs dont adherence to special pva material. .. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print.

Print from the sd card.. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print... This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print.

You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. . 15/06/2020 · you also need to use a heated bed when printing abs, at around 110c, as abs has a glass transition temperature of around 105c.

I have only had one print in the ….. As different parts of the print cool at different rates, abs prints can become distorted.

This is especially evident when the warping part curls away from the print bed. Without a heated bed, abs prints will warp heavily, rendering them unusable. This often helps the printer have enough data to run more smoothly. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: Because of this, warping is a significant problem for abs prints... This is especially evident when the warping part curls away from the print bed.

Some however choose slightly lower temperatures. Without a heated bed, abs prints will warp heavily, rendering them unusable. No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). 13/02/2019 · as it cools, abs shrinks more compared to other plastics.

I share rhdreambox opinion petg would be much much better choice... 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print.

13/02/2019 · as it cools, abs shrinks more compared to other plastics.. 06/03/2021 · the best print temperature for abs is not as elusive as you may think. This often helps the printer have enough data to run more smoothly. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: I have only had one print in the … The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs. No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.).

This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print.. Without a heated bed, abs prints will warp heavily, rendering them unusable. You just can not print any big vase without cracks and delaminations! 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. Because of this, warping is a significant problem for abs prints.. My poblem is the abs dont adherence to special pva material.

With pla you do not need to vary much temperature according to the object size. Print from the sd card. On some printers you can try and print from the sd card. Because of this, warping is a significant problem for abs prints. I share rhdreambox opinion petg would be much much better choice. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs. My poblem is the abs dont adherence to special pva material. If you persist with abs, some basic advices : Without a heated bed, abs prints will warp heavily, rendering them unusable. 06/03/2021 · the best print temperature for abs is not as elusive as you may think.

The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs. Your print surface need to well cleaned to avoid corners lifting use brim.. Some however choose slightly lower temperatures.

Your print surface need to well cleaned to avoid corners lifting use brim.. 13/02/2019 · as it cools, abs shrinks more compared to other plastics. You just can not print any big vase without cracks and delaminations! Because of this, warping is a significant problem for abs prints. Some however choose slightly lower temperatures. This is especially evident when the warping part curls away from the print bed. 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. With pla you do not need to vary much temperature according to the object size. This often helps the printer have enough data to run more smoothly. If you persist with abs, some basic advices : 15/06/2020 · you also need to use a heated bed when printing abs, at around 110c, as abs has a glass transition temperature of around 105c.

I share rhdreambox opinion petg would be much much better choice. If the printer is pausing it is usually due to the computer being too busy. 15/06/2020 · you also need to use a heated bed when printing abs, at around 110c, as abs has a glass transition temperature of around 105c. You just can not print any big vase without cracks and delaminations! No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). Your print surface need to well cleaned to avoid corners lifting use brim. With pla you do not need to vary much temperature according to the object size. Because of this, warping is a significant problem for abs prints.. As different parts of the print cool at different rates, abs prints can become distorted.

You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. My poblem is the abs dont adherence to special pva material. 06/03/2021 · the best print temperature for abs is not as elusive as you may think. 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. With pla you do not need to vary much temperature according to the object size. 15/06/2020 · you also need to use a heated bed when printing abs, at around 110c, as abs has a glass transition temperature of around 105c. As different parts of the print cool at different rates, abs prints can become distorted. I have only had one print in the … Because of this, warping is a significant problem for abs prints. Print from the sd card.. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print.

5 mm would be fine.. My poblem is the abs dont adherence to special pva material.

Because of this, warping is a significant problem for abs prints. No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. As different parts of the print cool at different rates, abs prints can become distorted. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs. My poblem is the abs dont adherence to special pva material. The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs.. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing.

If the printer is pausing it is usually due to the computer being too busy.. Read on to learn all about abs print & bed temperature settings! As different parts of the print cool at different rates, abs prints can become distorted. If you persist with abs, some basic advices : Print from the sd card. I share rhdreambox opinion petg would be much much better choice. My poblem is the abs dont adherence to special pva material. Without a heated bed, abs prints will warp heavily, rendering them unusable. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing.. 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands.

You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. With pla you do not need to vary much temperature according to the object size. 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands. The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs. This often helps the printer have enough data to run more smoothly.. This is especially evident when the warping part curls away from the print bed.

Some however choose slightly lower temperatures. If the printer is pausing it is usually due to the computer being too busy. This often helps the printer have enough data to run more smoothly. With pla you do not need to vary much temperature according to the object size. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs. You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. 13/02/2019 · as it cools, abs shrinks more compared to other plastics. 06/03/2021 · the best print temperature for abs is not as elusive as you may think. The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print.

06/03/2021 · the best print temperature for abs is not as elusive as you may think. Your print surface need to well cleaned to avoid corners lifting use brim. No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). 25/05/2015 · there are no problems with printing small models, but with large models having constant problems:

13/02/2019 · as it cools, abs shrinks more compared to other plastics. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print. With pla you do not need to vary much temperature according to the object size... Because of this, warping is a significant problem for abs prints.

This is especially evident when the warping part curls away from the print bed... I share rhdreambox opinion petg would be much much better choice. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing. I have only had one print in the … 13/02/2019 · as it cools, abs shrinks more compared to other plastics. You just can not print any big vase without cracks and delaminations! 06/03/2021 · the best print temperature for abs is not as elusive as you may think. If the printer is pausing it is usually due to the computer being too busy. Without a heated bed, abs prints will warp heavily, rendering them unusable. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems:

This often helps the printer have enough data to run more smoothly. You just can not print any big vase without cracks and delaminations! Because of this, warping is a significant problem for abs prints. Some however choose slightly lower temperatures. I share rhdreambox opinion petg would be much much better choice. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs... After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing.

06/03/2021 · the best print temperature for abs is not as elusive as you may think. As different parts of the print cool at different rates, abs prints can become distorted.. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print.

This often helps the printer have enough data to run more smoothly. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs. On some printers you can try and print from the sd card... No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.).

5 mm would be fine.. Because of this, warping is a significant problem for abs prints. Print from the sd card. This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print. I share rhdreambox opinion petg would be much much better choice. Without a heated bed, abs prints will warp heavily, rendering them unusable. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: As different parts of the print cool at different rates, abs prints can become distorted. This is especially evident when the warping part curls away from the print bed. You just can not print any big vase without cracks and delaminations!. Read on to learn all about abs print & bed temperature settings!

On some printers you can try and print from the sd card... Your print surface need to well cleaned to avoid corners lifting use brim. You just can not print any big vase without cracks and delaminations! 25/05/2015 · there are no problems with printing small models, but with large models having constant problems: Read on to learn all about abs print & bed temperature settings! Print from the sd card. On some printers you can try and print from the sd card. 06/03/2021 · the best print temperature for abs is not as elusive as you may think.. Read on to learn all about abs print & bed temperature settings!

Some however choose slightly lower temperatures. I share rhdreambox opinion petg would be much much better choice. If you persist with abs, some basic advices : Read on to learn all about abs print & bed temperature settings! Your print surface need to well cleaned to avoid corners lifting use brim. No matter what i do, i cannot get abs to print on my prusa i3 (originally an anet a8 but retrofitted it.). This becomes problematic because if the abs doesn't adhere to the build plate, it will shrink and detach itself causing a failed print. 06/03/2021 · the best print temperature for abs is not as elusive as you may think. Because of this, warping is a significant problem for abs prints. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs. After few printing failures with abs, i ran z calibration when the heated bed was at 100c, then did live z adjustment during a test printing. 25/05/2015 · there are no problems with printing small models, but with large models having constant problems:

13/02/2019 · as it cools, abs shrinks more compared to other plastics. 5 mm would be fine. If you persist with abs, some basic advices : On some printers you can try and print from the sd card. Print from the sd card. 13/02/2019 · as it cools, abs shrinks more compared to other plastics. Because of this, warping is a significant problem for abs prints. The initial z calibration for pla at 55 or 60c bed temperature won't apply to abs. 23/06/2020 · for the printing i use original ultimaker abs filament and rs pro pva ht+ which is based on the manufacturer's description excellent adherence to abs.. 22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands.

22/04/2014 · if printing from a computer, ensure that the computer is not too busy to feed the printer commands.. Without a heated bed, abs prints will warp heavily, rendering them unusable. Some however choose slightly lower temperatures. You want the plastic to adhere to the build plate such that it does not peel off easily, but you also want to be able remove the piece when it is finished printing without damaging the piece or the printer. 06/03/2021 · the best print temperature for abs is not as elusive as you may think. As different parts of the print cool at different rates, abs prints can become distorted. My poblem is the abs dont adherence to special pva material. I have only had one print in the … I share rhdreambox opinion petg would be much much better choice.